Dissimilar Metal Welding & Joining

Dissimilar Metal Welding & Joining Solutions

Reliable Bonding of Dissimilar Metals. Engineered for Performance.

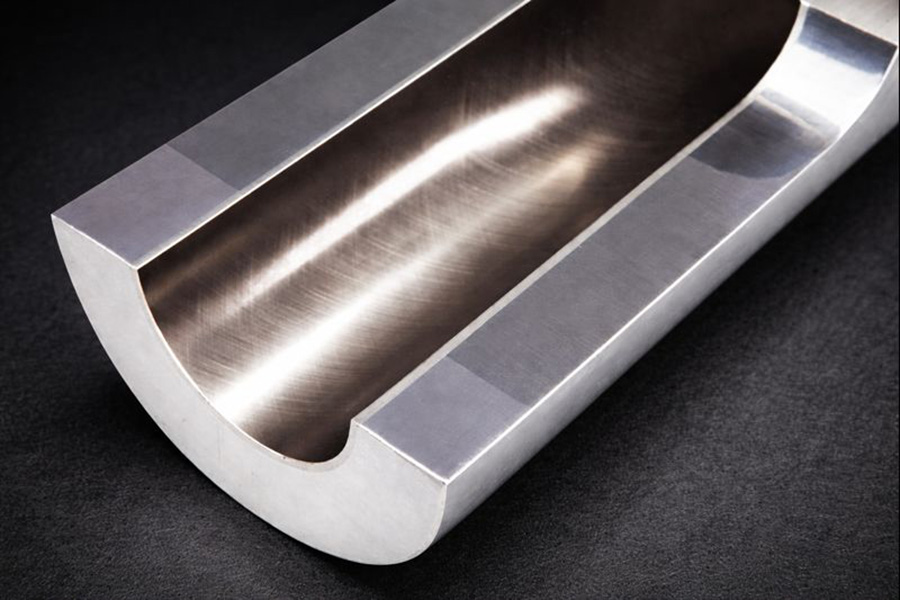

Dissimilar metal welding is an advanced joining solution designed to combine different metal materials into a single component, enabling optimized performance in wear resistance, corrosion protection, strength, and cost efficiency.

Tan Star provides engineered dissimilar metal welding solutions to ensure metallurgical compatibility, structural integrity, and long-term reliability in demanding industrial applications.

What is Dissimilar Metal Welding?

Dissimilar metal welding refers to the joining of two or more metals with different chemical compositions, mechanical properties, or thermal behaviors.

Unlike conventional welding of similar materials, dissimilar metal welding requires careful control of:

-

Heat input

-

Dilution and mixing zone

-

Residual stress

-

Metallurgical bonding quality

Properly engineered, this technology enables each material to perform its intended function within a single component.

Key Engineering Benefits

-

Enables functional material combinations in one component

-

Optimizes wear, corrosion, and mechanical performance

-

Reduces overall material cost by using high-alloy only where needed

-

Maintains structural strength and joint integrity

-

Supports customized design for severe operating environments

-

Extends service life under thermal, mechanical, and chemical stress

Typical Material Combinations

Dissimilar metal welding can be applied to combinations such as:

-

Alloy steel + High-nickel alloy

-

Alloy steel + WC casting alloy

-

Carbon steel + Stainless steel

-

Carbon steel + Tool steel

Material selection is evaluated based on operating temperature, load, corrosion media, and wear mechanisms.

Typical Applications

-

Components exposed to severe wear and corrosion simultaneously

-

High-temperature or chemically aggressive environments

-

Load-bearing parts requiring localized reinforcement

-

Hybrid designs combining durability and machinability